Zinc Plating vs. Hot-Dip Galvanising: Which Is Better?

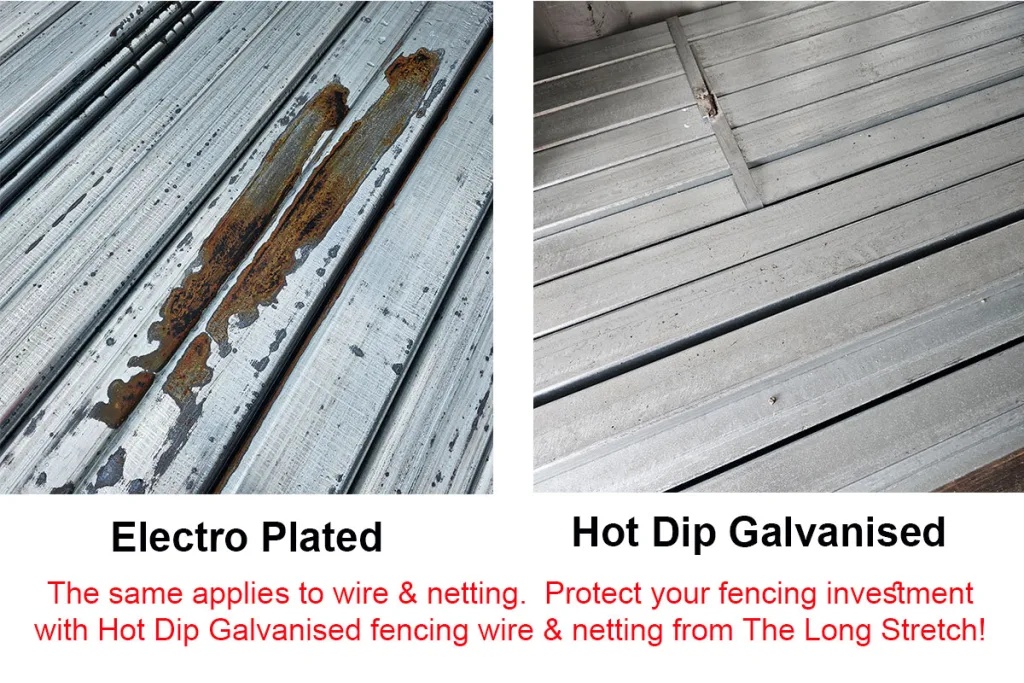

Both zinc plating and hot-dip galvanising are methods of applying a protective zinc coating to steel to prevent corrosion. However, the way the zinc is applied—and the resulting performance—differs significantly between the two.

Zinc Plating (Electroplating)

Process:

Zinc plating is done through electrochemical deposition, where a thin layer of zinc is applied to the steel surface using an electric current in a zinc salt solution.

Advantages:

- Smooth finish: Bright, uniform, and attractive for decorative or indoor use.

- Precise coating thickness: Ideal for parts with tight tolerances.

- Lower initial cost per item: Good for small, low-stress components.

Disadvantages:

- Thin coating (5–30 g/m²): Minimal corrosion protection outdoors.

- Poor bushfire resistance: Thin zinc layer offers little thermal insulation.

- Short lifespan in outdoor/rural use: Coating breaks down quickly in moisture, salt, or manure.

- Not suitable for structural or heavy-duty applications.

Bushfire Impact:

Zinc plating offers minimal protection in bushfires. The thin coating will vaporise or break down under intense heat, leaving the steel exposed to rust and structural failure.

Longevity:

Typically 1–3 years outdoors in moderate environments, much less in coastal, acidic, or high-rainfall areas.

Workability:

- Easier to machine or form due to thinner coating.

- However, coating can crack or flake during bending or welding.

Hot-Dip Galvanising

Process:

Hot-dip galvanising involves immersing steel in molten zinc, forming a thick, metallurgically bonded coating that covers all surfaces—including edges, welds, and internal cavities.

Advantages:

- Thick zinc coating (40–600 g/m²): Outstanding rust and corrosion resistance.

- Durable and hard-wearing: Withstands physical impact, animal pressure, and extreme weather.

- Excellent fire resistance: Steel remains structurally sound in bushfires; zinc doesn’t ignite or melt easily.

- Ideal for structural and outdoor use: Long lifespan in all Australian conditions.

Disadvantages:

- Rougher surface finish: Not suited for decorative indoor use.

- Higher upfront cost per item: But offset by much lower maintenance costs.

- Slightly reduced precision in tight tolerances: Not ideal for small mechanical parts.

Bushfire Impact:

Hot-dip galvanised steel performs exceptionally well in bushfires. The zinc coating acts as a heat shield and doesn’t degrade quickly, helping maintain the structure’s integrity under high temperatures.

Longevity:

Can last 20–50 years outdoors, even longer in dry inland regions. Coastal and high-moisture areas typically see 15–25 years with minimal maintenance.

Workability:

- Tougher to machine or weld (unless welding is done before galvanising).

- May require coating touch-up after cutting or drilling.

Summary Comparison Table

| Feature | Zinc Plating | Hot-Dip Galvanising |

|---|---|---|

| Coating Thickness | 5–30 g/m² | 40–600 g/m² |

| Corrosion Resistance | Low | Excellent |

| Lifespan (Outdoors) | 1–3 years | 20–50 years |

| Fire Resistance | Poor | High |

| Cost (initial) | Lower | Higher |

| Maintenance Needs | High | Low |

| Best Use Cases | Indoor, decorative parts | Rural fencing, stock yards, gates, infrastructure |

| Surface Finish | Smooth, shiny | Matte, industrial |

| Workability | High (but coating flakes easily) | Medium (pre-weld preferred) |

Final Verdict for Rural Applications

For Australian farms, stations, and outdoor infrastructure exposed to weather, livestock, and bushfires, hot-dip galvanising is vastly superior. While zinc plating may be appropriate for light-duty indoor components, it simply can’t match the durability and lifespan of hot-dipped steel in real-world farm environments.